The National Institute for Aviation Research at Wichita State University is home to 19 cutting-edge labs that partner with companies spanning the globe. One of those labs is the newly created Advanced Technologies Lab for Aerospace Systems (ATLAS).

What is ATLAS?

Launched in spring of 2019, ATLAS is a multi-disciplinary manufacturing ecosystem that uses automation with machine-learning and artificial intelligence to increase manufacturing efficiency. It was created to do what WSU does best: help meet industry’s needs.

ATLAS provides engineers and educators with the skills and expertise to efficiently prepare for the Factory of the Future and aids the current workforce in seamlessly adapting to advancements in many industries.

ATLAS as an applied learning experience

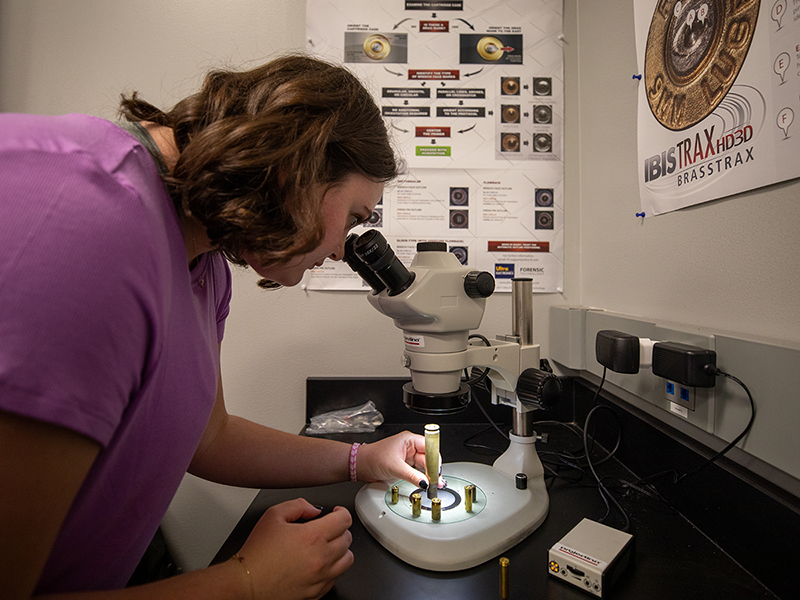

ATLAS employs 100 researchers, including 60 students, ensuring a hands-on applied learning experience for those involved.

Tomas Lorik, ATLAS Research Engineer, recently made the transition from undergraduate Research Assistant to full-time staff member. Prior to employment, Tomas served in the U.S. Army.

“During the transition from military service to civilian life, I was looking for the well-structured work environment. I enjoyed the applied learning eco system at NIAR that enabled me to support research programs from NASA, FAA and U.S. Navy,” says Lorik. “One of the unique aspects of working at NIAR is the direct application of undergraduate studies to real world problems, further solidifying advanced engineering concepts from the classroom."

Since 2019, with the support of industry and federal defense and economic program, ATLAS has acquired close to $30 million worth of manufacturing, inspection and testing equipment in order to accommodate multiple federal and industry-sponsored research projects, says Dr. Waruna Seneviratne, director of ATLAS.

Goals of ATLAS

When creating ATLAS, Seneviratne says, he wanted to invest in automation, machine learning algorithms, and materials that could reduce the number of manufacturing defects.

“We had a good solution and plan,” said Seneviratne.

Another goal of ATLAS is to extend the research and development capabilities of the aerospace industry by providing hands-on learning. ATLAS works with the Department of Defense, NASA and several federal agencies, including Homeland Security.

director of ATLAS

Through ATLAS, industry partners and small businesses or individuals can develop prototypes or test materials and experiment with industry-scaled equipment that would typically require an equipment manufacturer or teaching-scaled equipment from a college or university.

“Our mission is to promote automated manufacturing as a whole. We want them to experiment and see what works best,” Seneviratne said.

How it all works

Every research topic follows the same protocols. First, ATLAS researchers create an industry advisory group to plan the research topic and get feedback. Then they create a project work plan. From there, they test the research topic in the computer lab and then create it in the manufacturing lab.

“We approach every research topic asking how we can solve the problem and who and what do we need to get there,” said Seneviratne.

One of ATLAS’ biggest projects is Modeling for Affordable Sustainable Composites (MASC) for the Air Force Research Lab.

“We are developing protocols to increase efficiency, productivity, and quality of future aircraft manufacturing," Seneviratne said. "This future involves a lot of programming and simulations as well as developing artificial intelligence and machine learning algorithms. It is almost like a computer game.”

For more information, watch this interview with Seneviratne.