Research Activity: As part of a FAA JAMS research program, WSU-NIAR is leading an effort to develop standardized test methods for configurations at the detail / element levels of a building block that interrogate common design features of additively manufactured (AM) parts such as overhangs, wall thickness, radii, holes, fastener and lug attachments, etc. This program will aim to reduce the complexity of certifying AM parts that contain multiple or even single design features.

Background Discussion - Part Families and Feature Families:

- The FAA recognizes part families for seats. They are used for design certification

purposes (initial certification and design changes). The concept of a family of seats

is a design philosophy. A family of seats is a group of seat assemblies built from

equivalent components in the primary load path. The intent of the family concept is

to permit a simplified test article selection process. If the components in the seat

design are carefully considered in advance, the initial series of tests performed

as part of the original design certification may substantiate the majority or all

of the seat family members for compliance with § 25.562. When a family of seats is

identified, test article selection will minimize the amount of testing required and

maximize the usability of the data generated. Assuming the family definition is robust,

modifications to family members can be made or new models can be added to the family.

In principle, the seats that have been tested are determined to be critical for the

parameters being measured, and any subsequent comparison should be made against the

critical configuration.

- In summary, a family of seats is created where the seats have “equivalent components” in the primary load path. A worst case test article is selected to provide the required test data for §25.562 that is used to substantiate all the seats in the family (normally each seat would have to be individually tested).

- The seat part family is used for design certification purposes only.

- AM may also benefit from part families. There are some industry activities in this area aimed at streamlining the path to design certification. They presumably, like the seats, will require testing one representative worst-case part out of the family for initial certification, and then use that data to substantiate the rest of the parts in the family. It is expected these parts will have the same criticality and functions in order to be part of a family.

- There is another possible grouping of AM parts, and that would be a feature-based family. While a part family would require all members of the family to have the same function, criticality and general certification requirements, there may be another grouping of purely geometric/build features that are common across parts of different functions and criticalities. For example, thin wall hollow tubes may be built for non-structural ducting or be used as a structural torque tube.

- One possible purpose of a Feature Family is for qualification of production facilities and/or maintenance organizations to produce types of parts with specific build features under defined material and process specifications (i.e., each Feature Family “approval” would be limited to a single material and process). This is essentially the same as the existing equivalence exercise at the simple coupon level, but introduces more complexity.

- Another possible use of test data for various geometric features is to support structural analysis. Certain geometric features will provide strength debits, which can be used as point-design data for more complex configurations. It may be possible to develop public databases with this information.

Project Goal:

We are asking the steering committee to help define the scope of the project, by identifying usefulness for mid-level building block test data. While we have identified that we want to investigate common geometrical features, we have not yet identified the purpose.

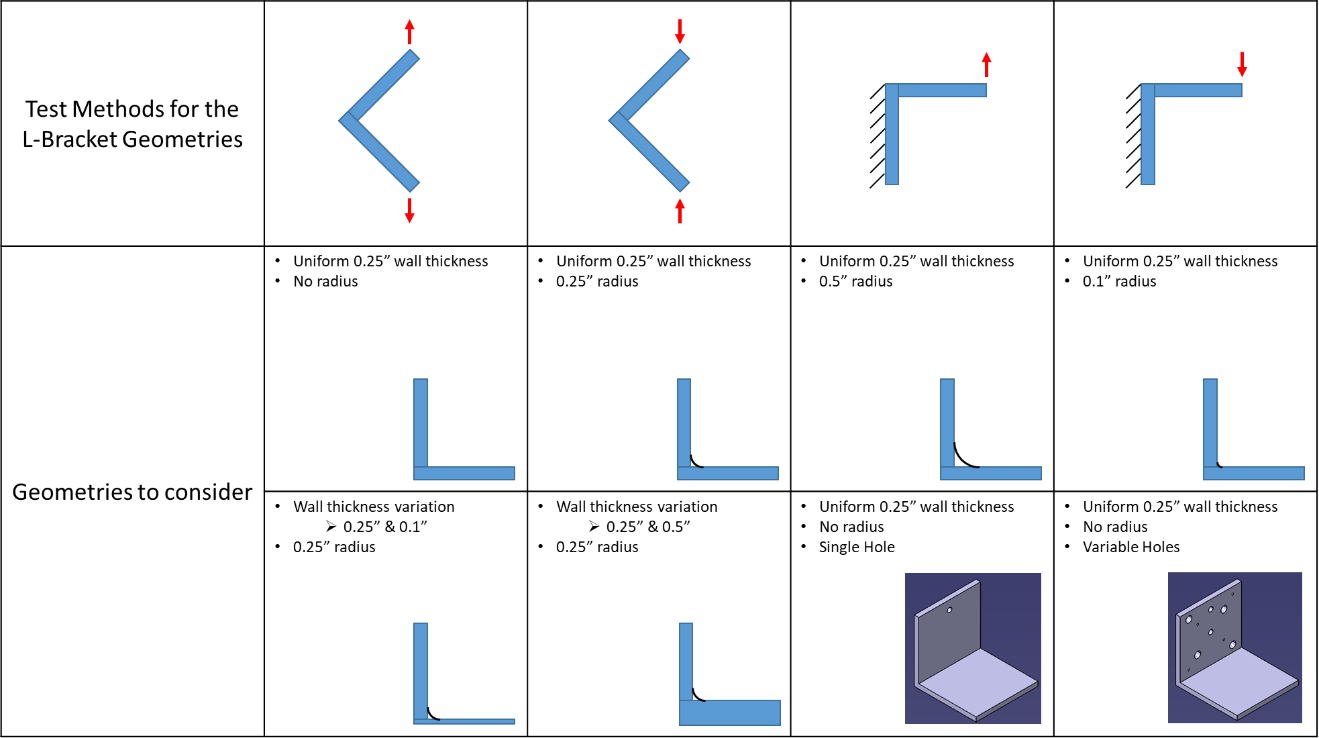

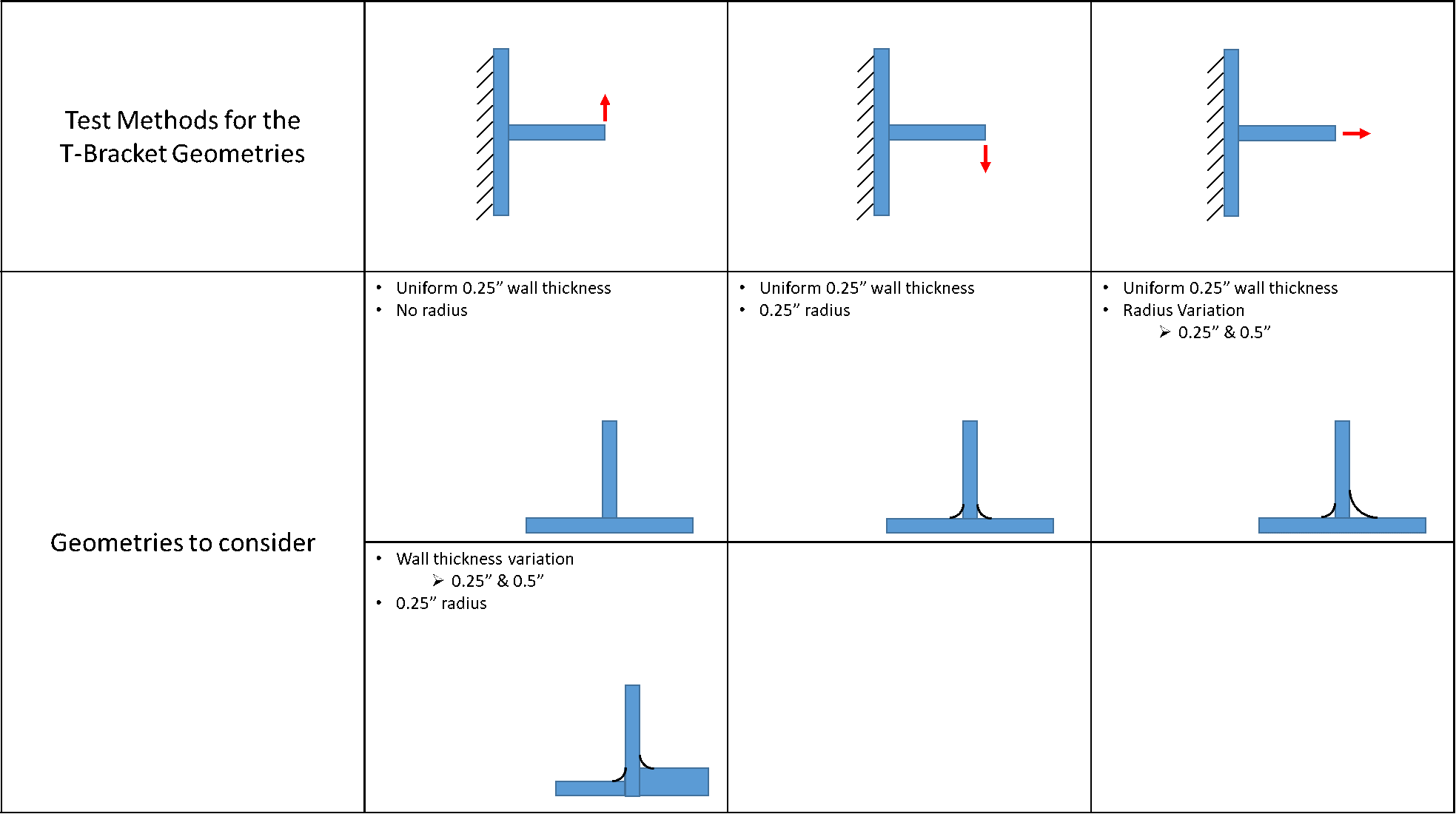

Example Test Article Configurations:

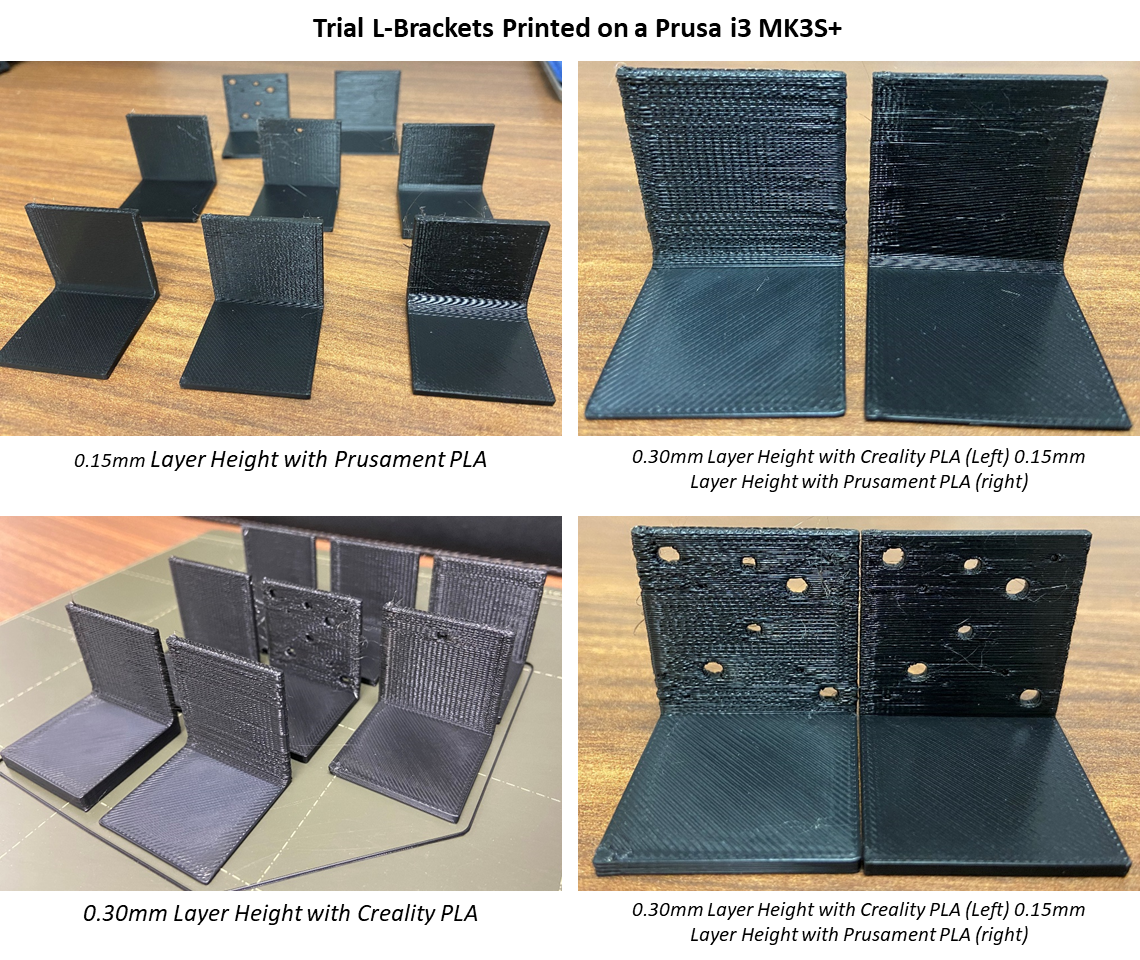

One potential element for investigation of the selected scope could include an L-Bracket or T-Bracket with varying features and geometric designs shown below.