Project Innovation Hub

John Bardo Center, Room 105 | 106 | 112 | 203 | 327

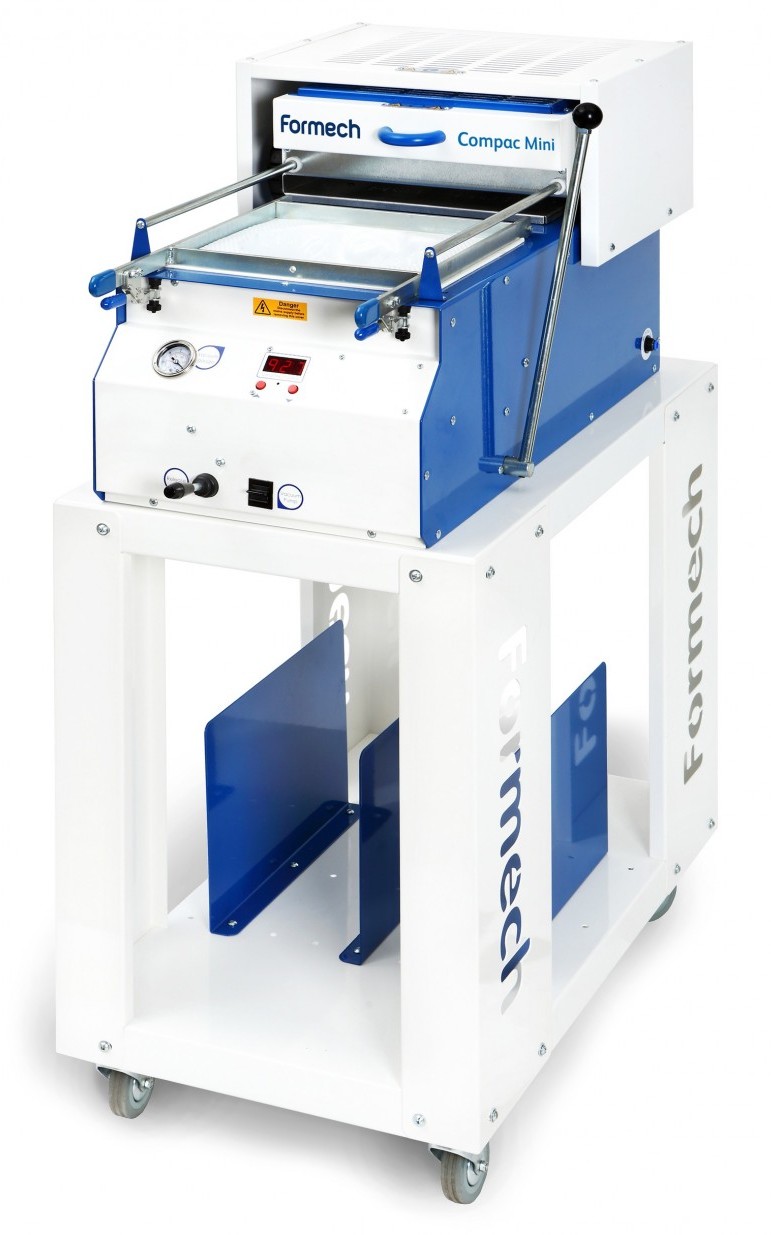

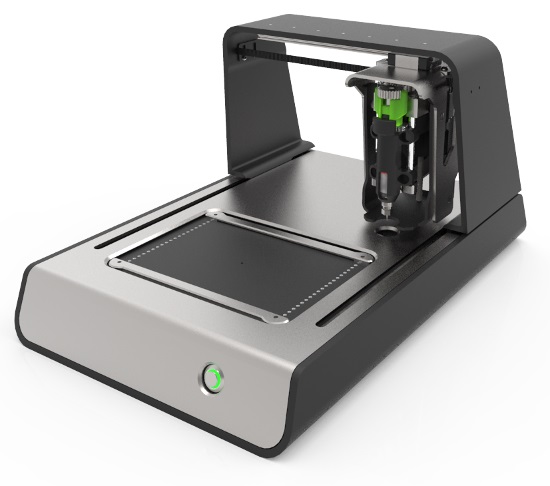

Our lab is outfitted to support a wide range of fabrication and prototyping activities. With access to tools such as laser cutters, 3D printers, CNC mills, and more, we are fully equipped to handle everything from precision components to rapid prototyping. See below for services we offer and the full range of equipment available.

Services We Offer

Teaching and Research Support

- Research and instructional support for WSU faculty and staff

- Research and project support for WSU students

- Guidance in project planning and development

- Collaboration on multi-disciplinary design projects

- Training and mentorship in fabrication techniques and equipment usage

Prototyping and Fabrication

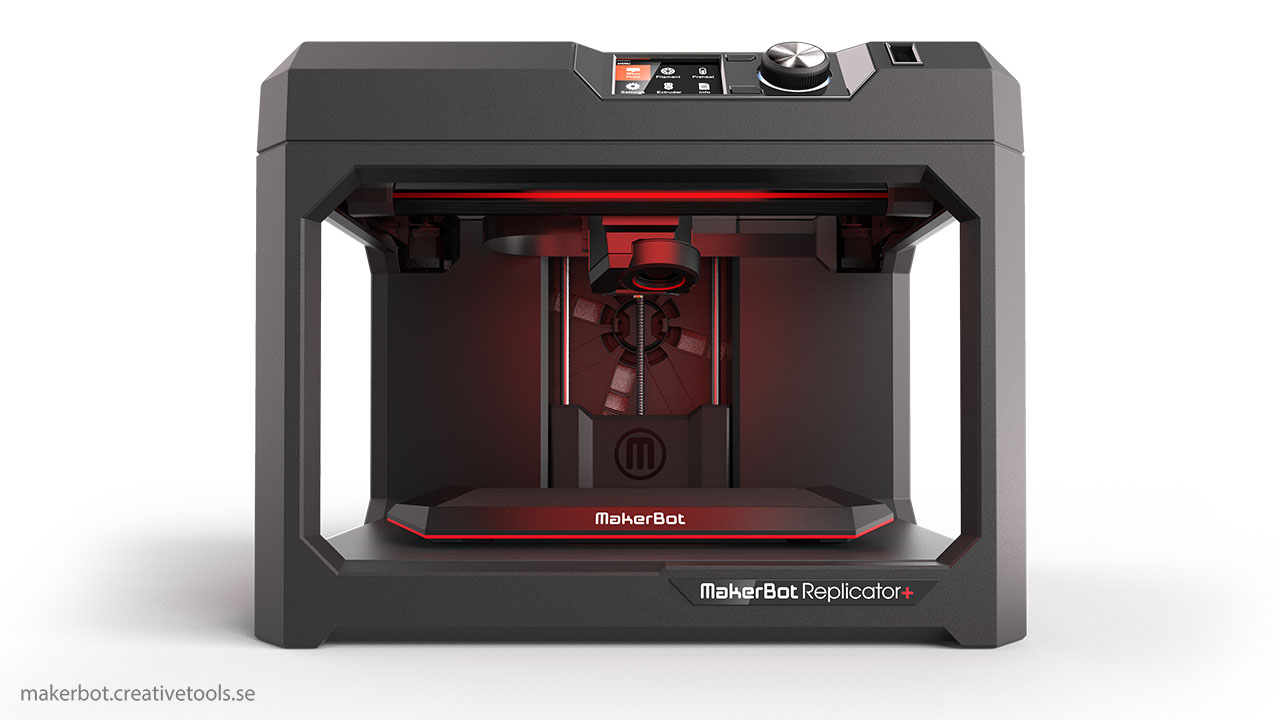

- Rapid prototyping using additive manufacturing (3D printing)

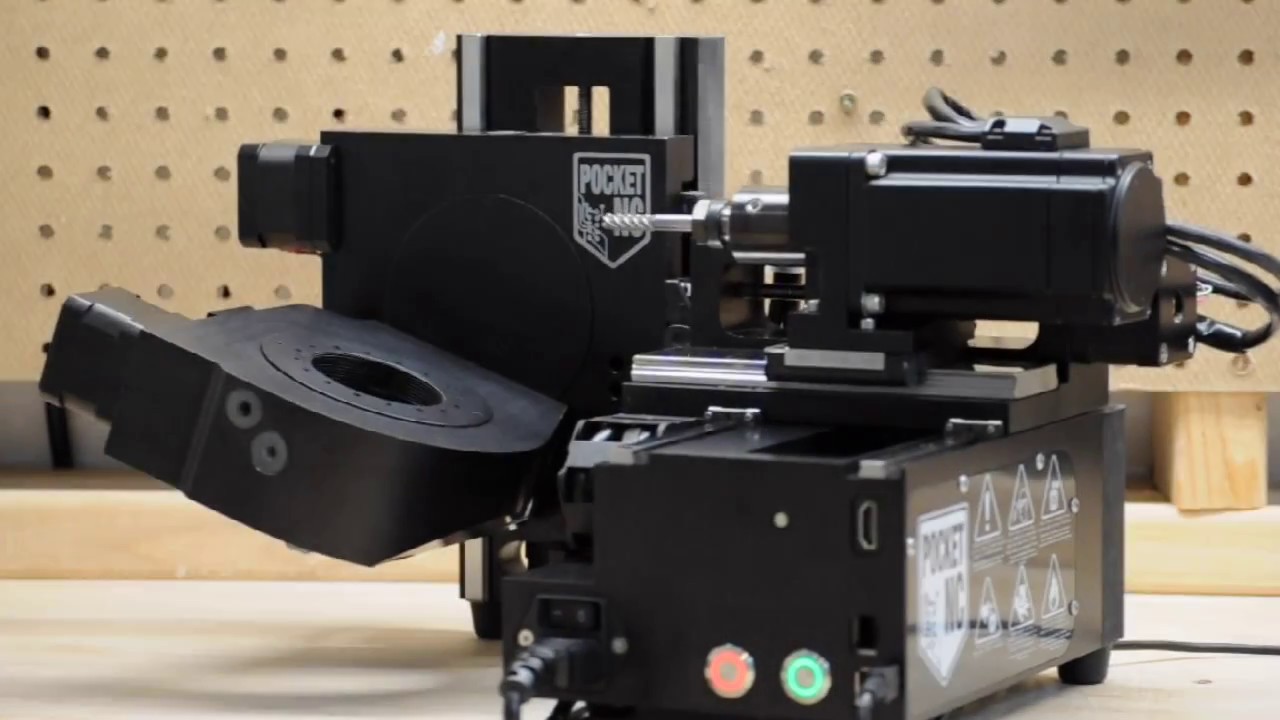

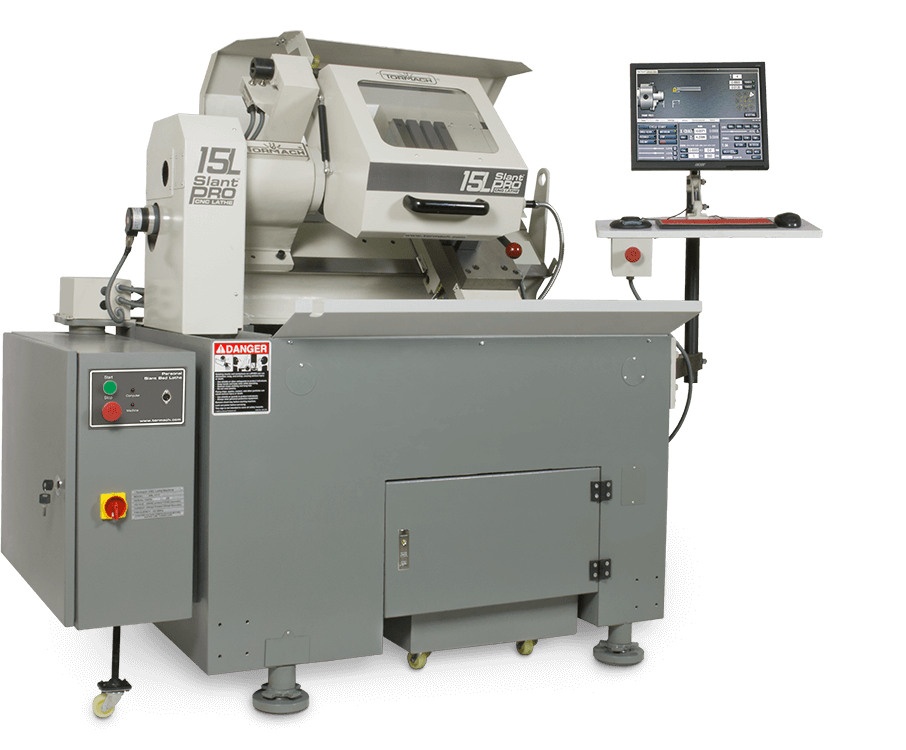

- CNC machining for custom parts, fixtures, and assemblies

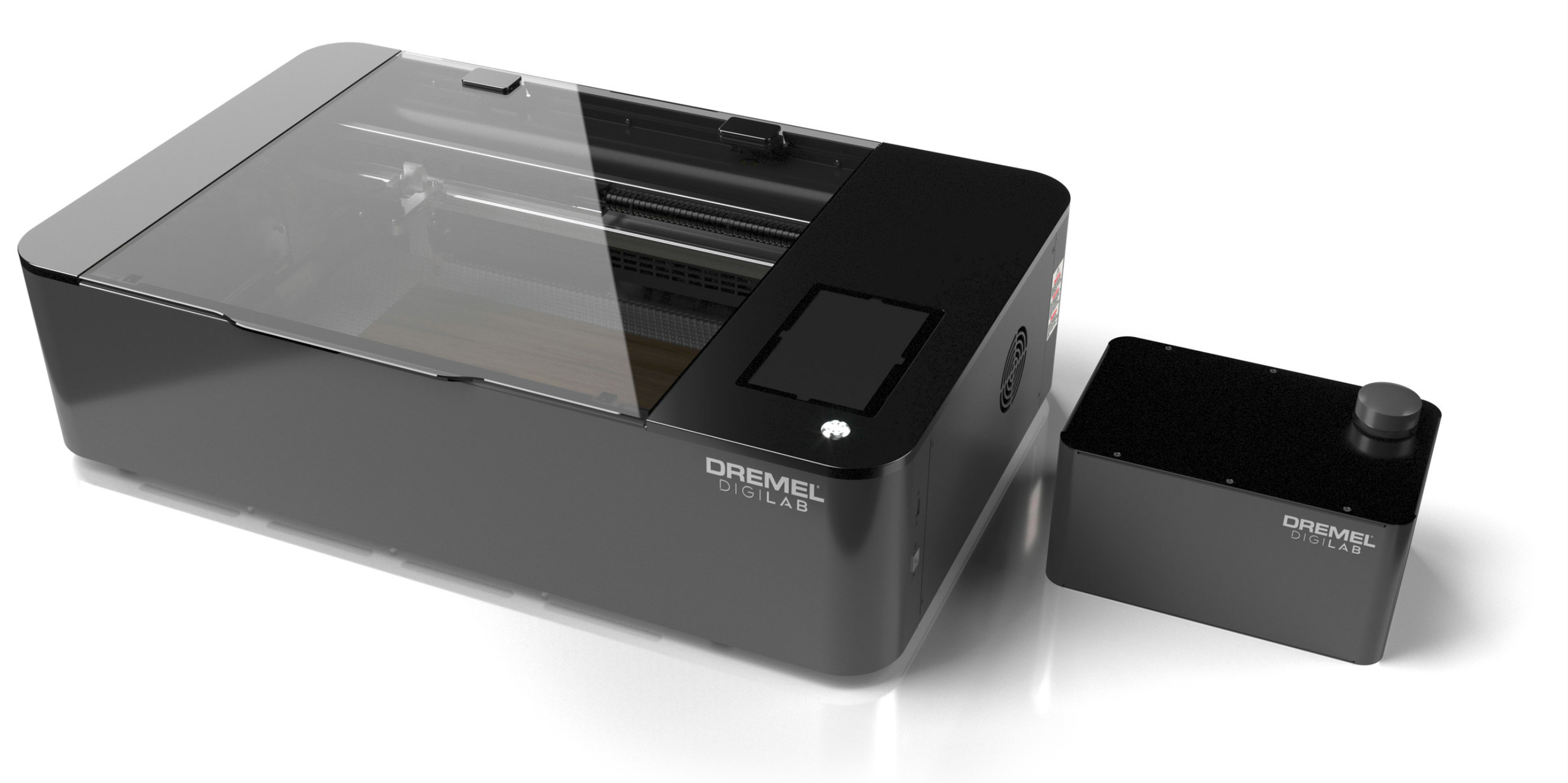

- Laser cutting and engraving

- CNC routing, milling, and turning

- CNC plasma and waterjet cutting

- Prototype iteration support

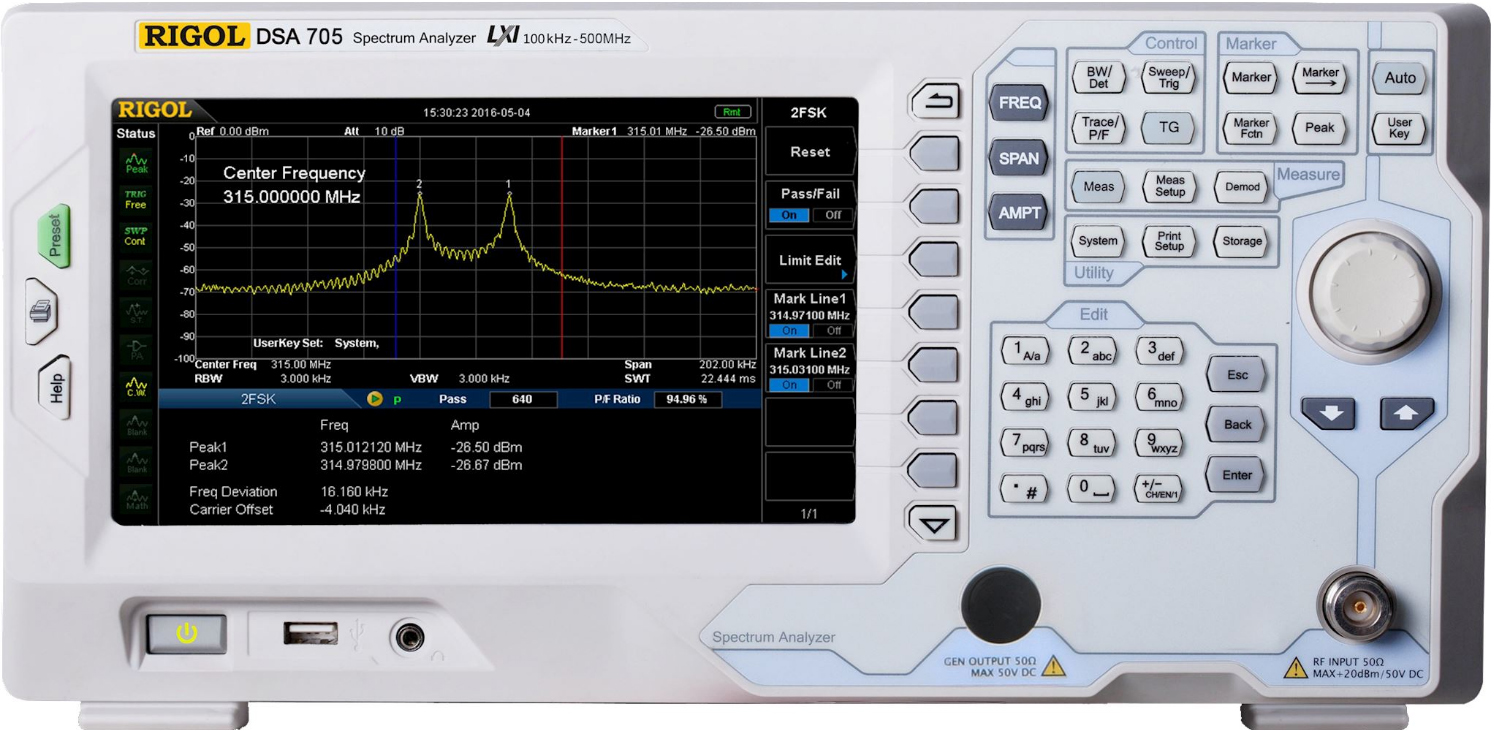

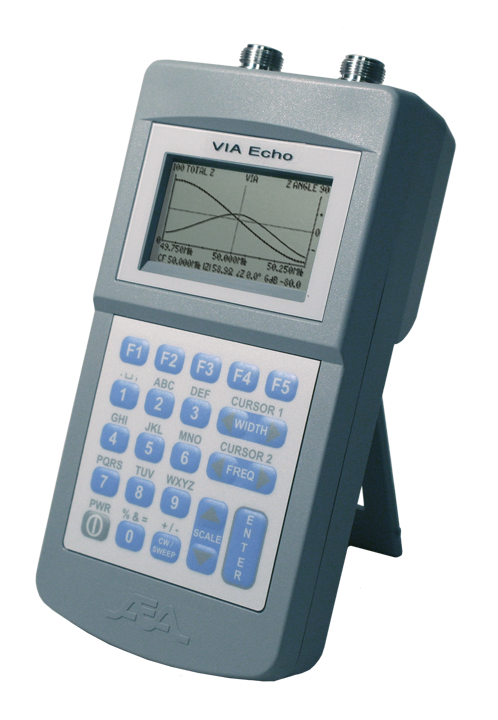

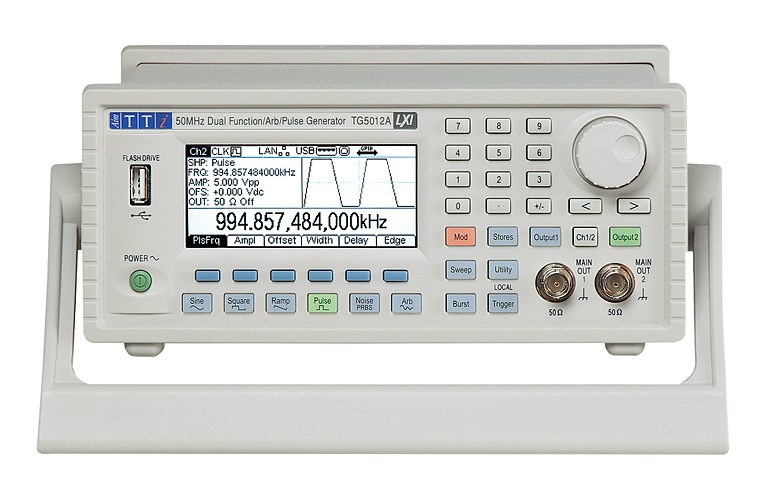

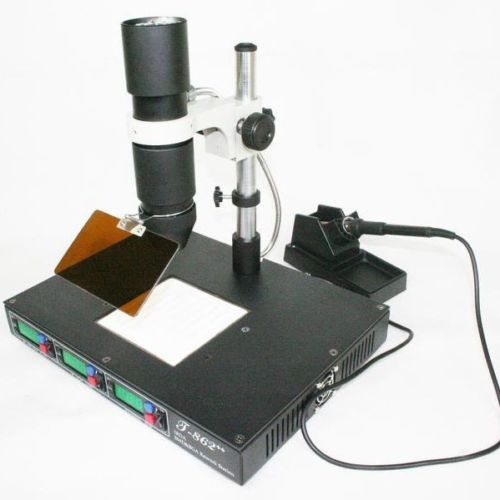

Electronics

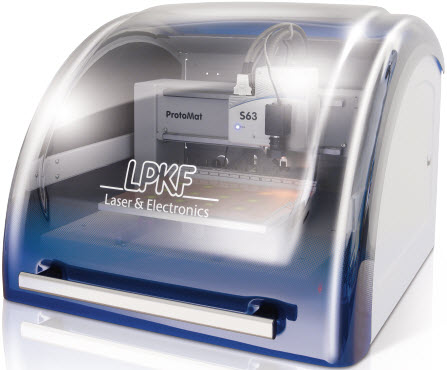

- Prototype PCB design and fabrication

- Prototyping for embedded systems and electronics

- Testing and troubleshooting of electronic components

- Benchtop rework and repair

- Basic programming

Mechanical Design and Assembly

- Conceptual design and 3D modeling

- 3D scanning

- Functional testing and design iteration

- Assistance with design-for-manufacturability (DFM) practices

Collaboration Opportunities

Our lab is open to students, faculty, campus partners, and external partners. Whether you're working on a research project, developing a product prototype, or refining an existing design, our team is here to help.

For more information on how we can assist with your next project, please see below.

- WSU students, faculty, staff and campus partners: Please use the following link to submit a request for assistance in TDX. ENGR Research or Projects Ticket: Help Me Make Something

- Community partners, makers, and entrepreneurs: Please email Nathan Smith with any questions or requests for quotes and/or services.

3D Printing

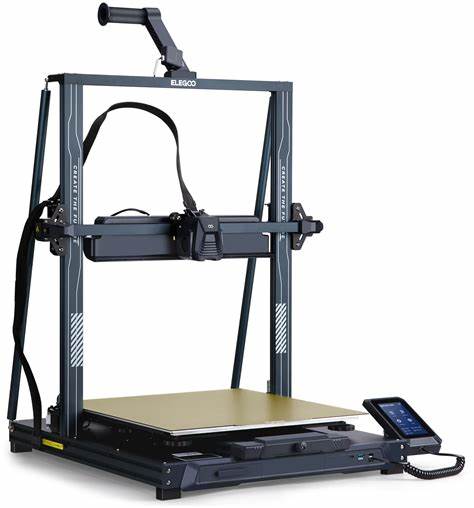

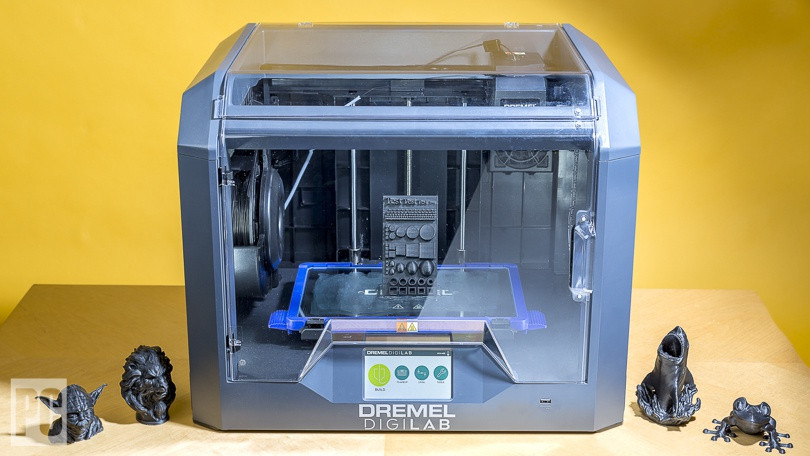

FDM Printing

- Standard Filament (PLA, ABS, TPU, PETG) = $0.06/g

- Composite Material = $0.10/g

- 3DP PLA (Large Format) = $0.12/g

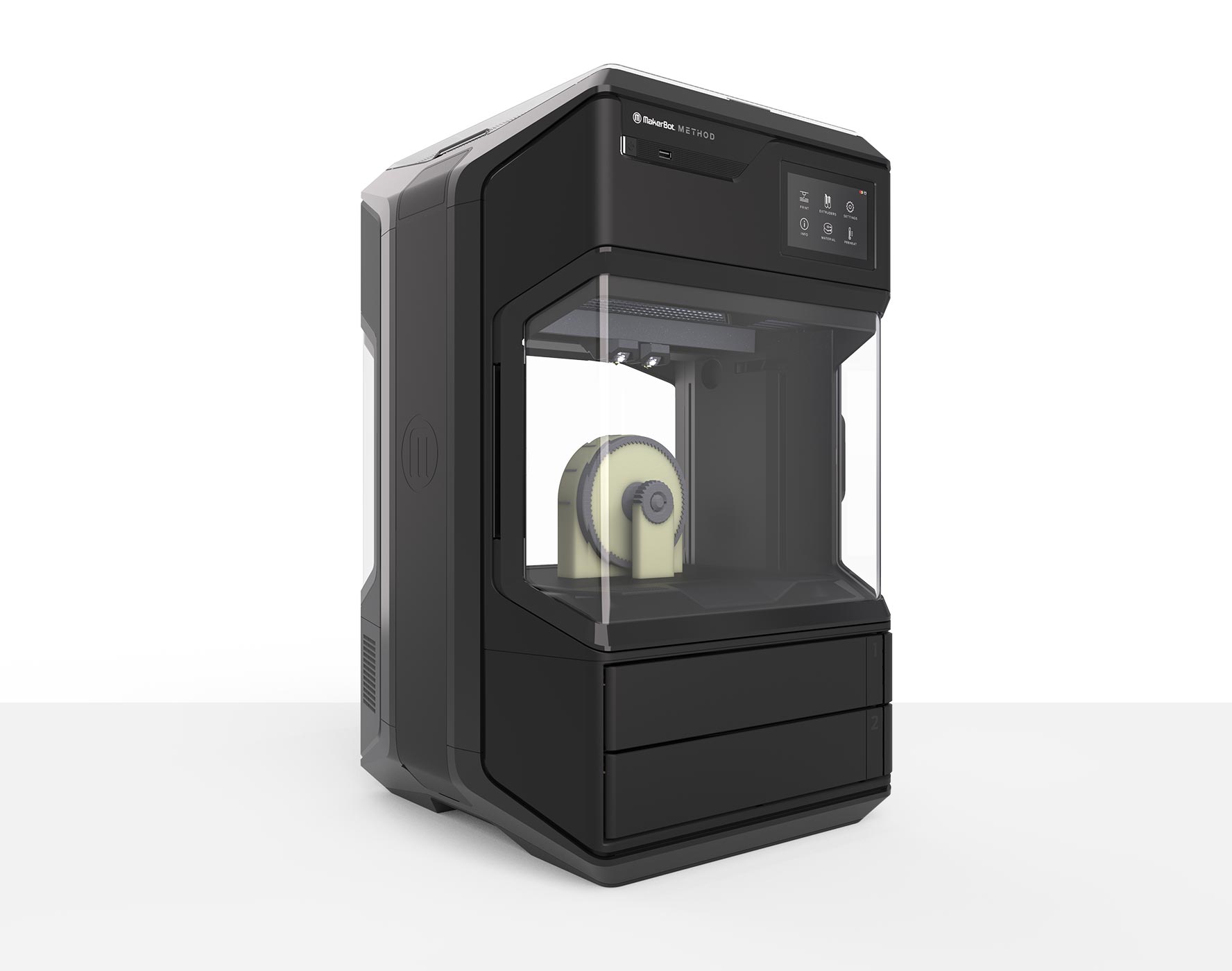

- Method PLA Tough = $0.10/g

- Method PVA = $0.20/g

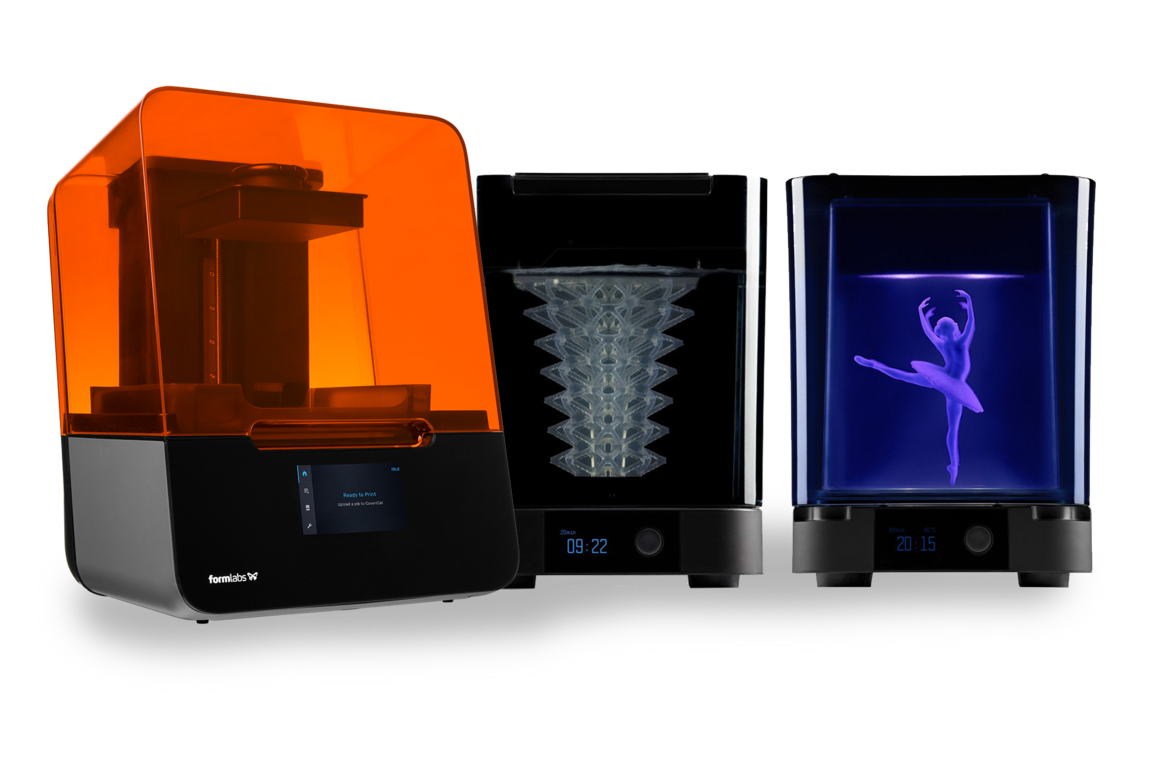

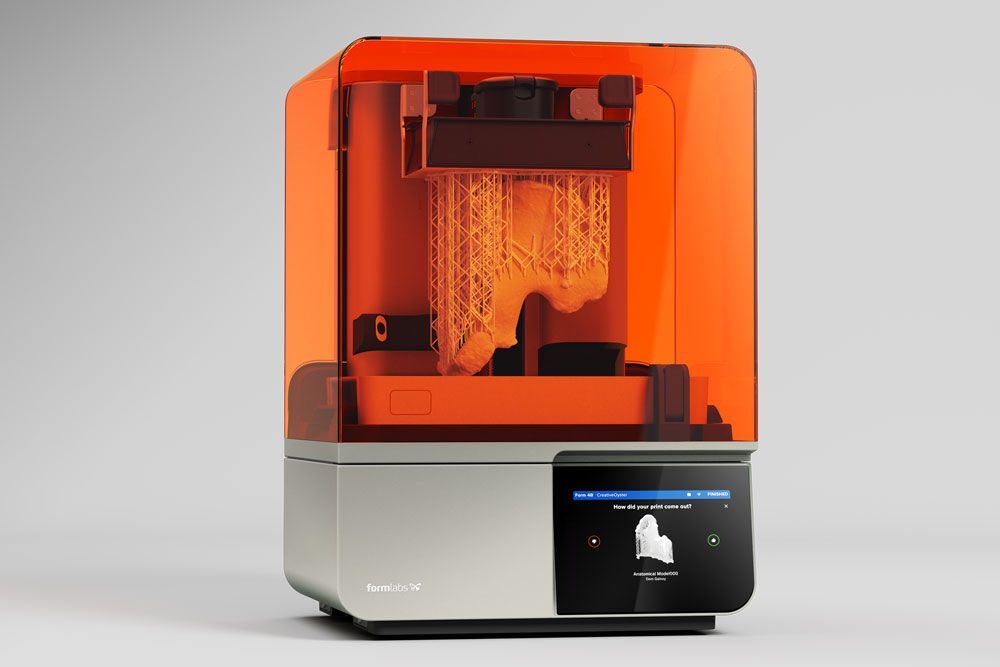

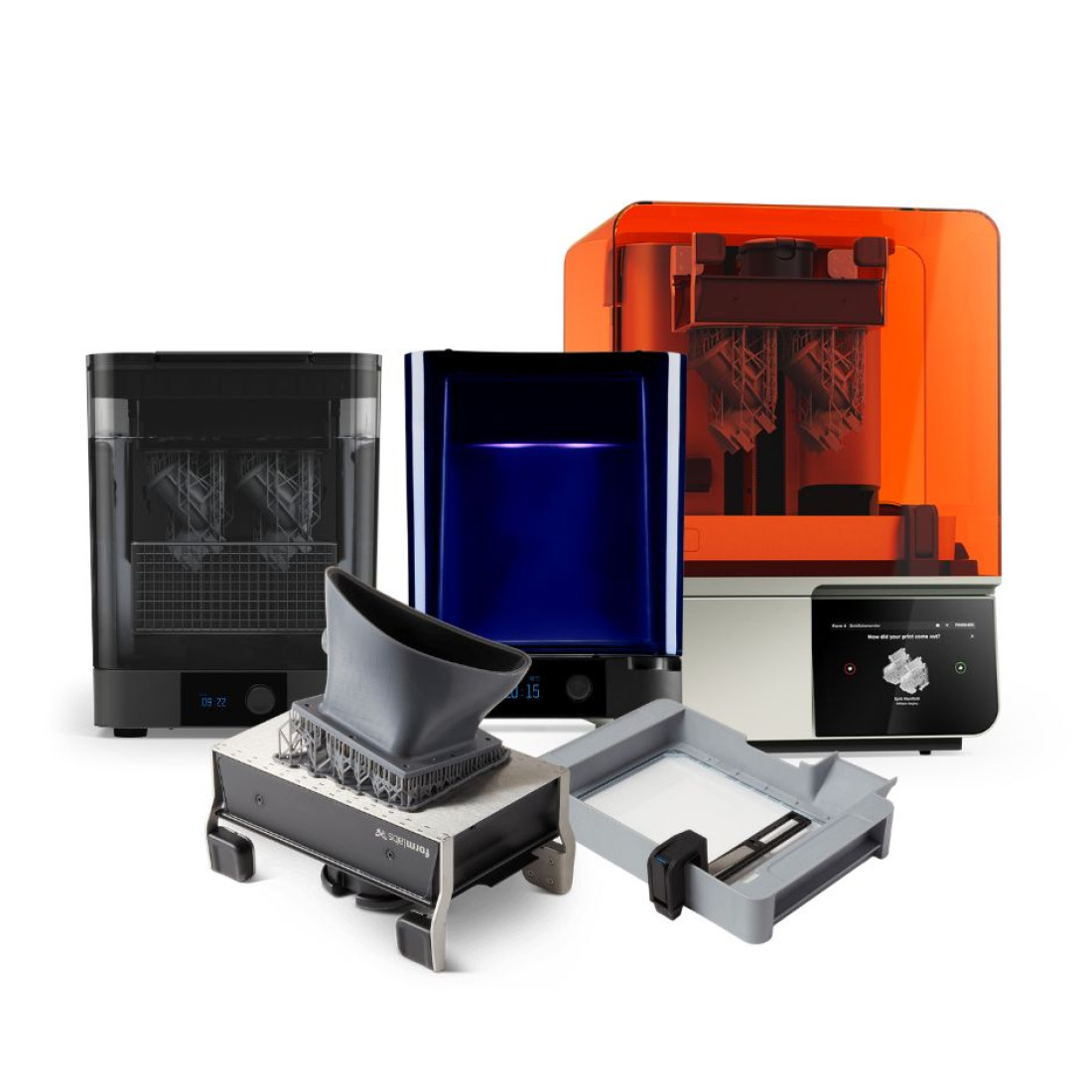

SLA Printing

- Standard Resins = $0.15/mL

- Flexible Resins = $0.35/mL

- Wax Resin = $0.50/mL

- Biocompatible & Specialty Resins = Material prices vary

SLS Printing

- Nylon 12 powder = $1.00/g for first 50g ($0.60/g for everything above 50g)

Waterjet Cutting

- Wazer Waterjet = $1.50/min

- ProtoMAX Waterjet = $2.00/min

Laser Cutting/Engraving

- All Machines = $0.12/min

Plasma Cutting

- CNC Plasma = $0.12/min

-

-

Safety Rules:

- Before operating equipment and tools, make sure that you are authorized. Do not use any tools or equipment without proper safety and usage instructions.

- Report any injuries/accidents to a lab mentor immediately.

- Safety glasses and hearing protection are required in the Innovation Hub when equipment and tools are in use, and as specified.

- Closed toe shoes required when working with Innovation Hub equipment.

- Clothing and jewelry that could become caught in equipment are prohibited. Long hair should be properly secured so it does not get caught in machines.

- Be aware of the locations of first aid, fire, and safety equipment.

- Never walk away from equipment in use.

- Keep fingers clear of the point of operation for equipment by using tools such as push sticks or hooks.

- Working alone is prohibited.

- Safety is your top priority within the Innovation Hub. If you are not sure what to do, ask!

Common Sense Guidelines:

- Do not remove tools from the Innovation Hub.

- Clean your work areas immediately after completing use of equipment and workspaces.

- Report any damaged or inoperable equipment to a lab mentor immediately.

Lab Use:

Students are expected to provide their own construction materials and supplies. The Innovation Hub will supply the equipment, training, and the space to work on their projects.

-

-