Equipment List

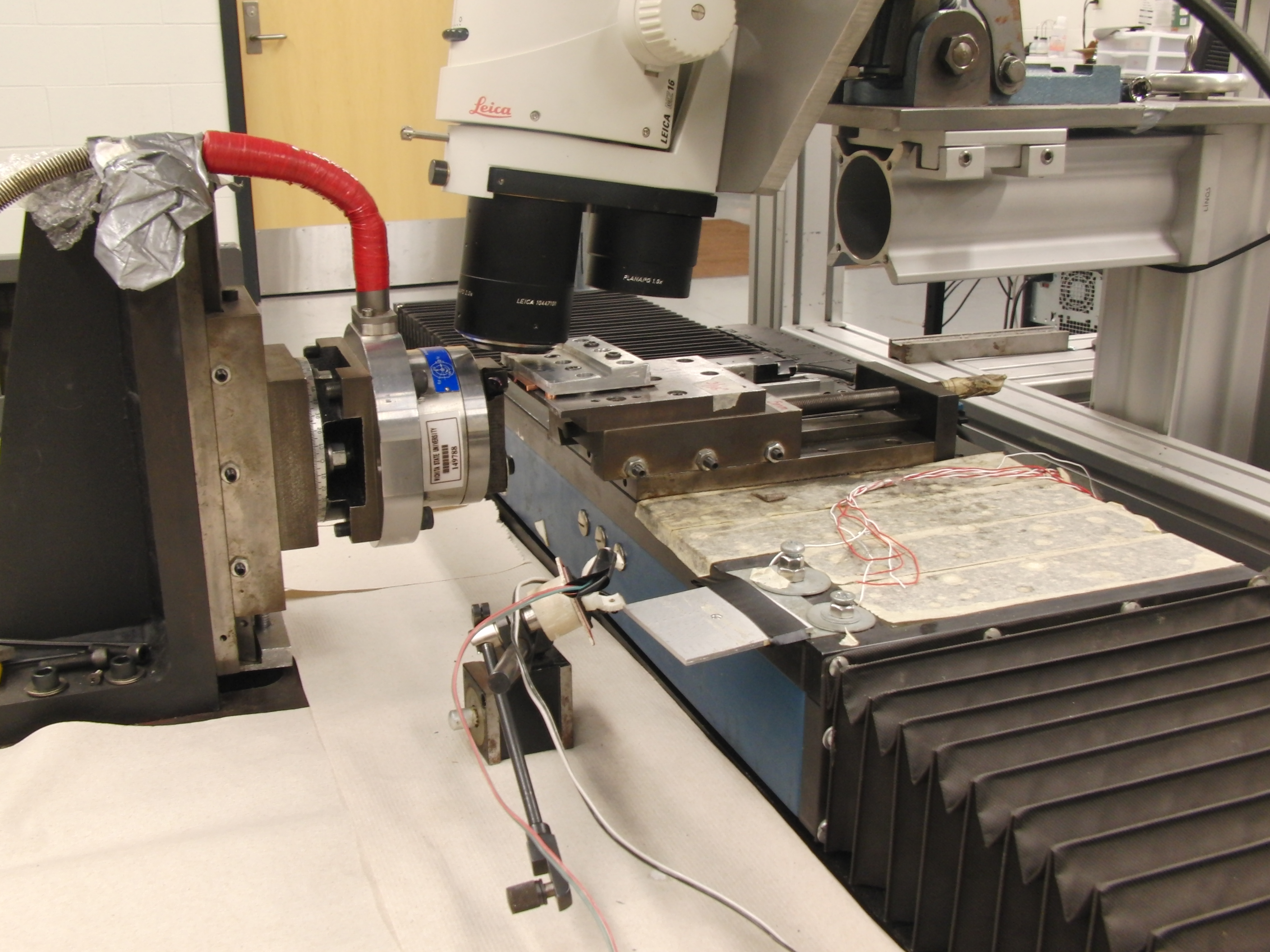

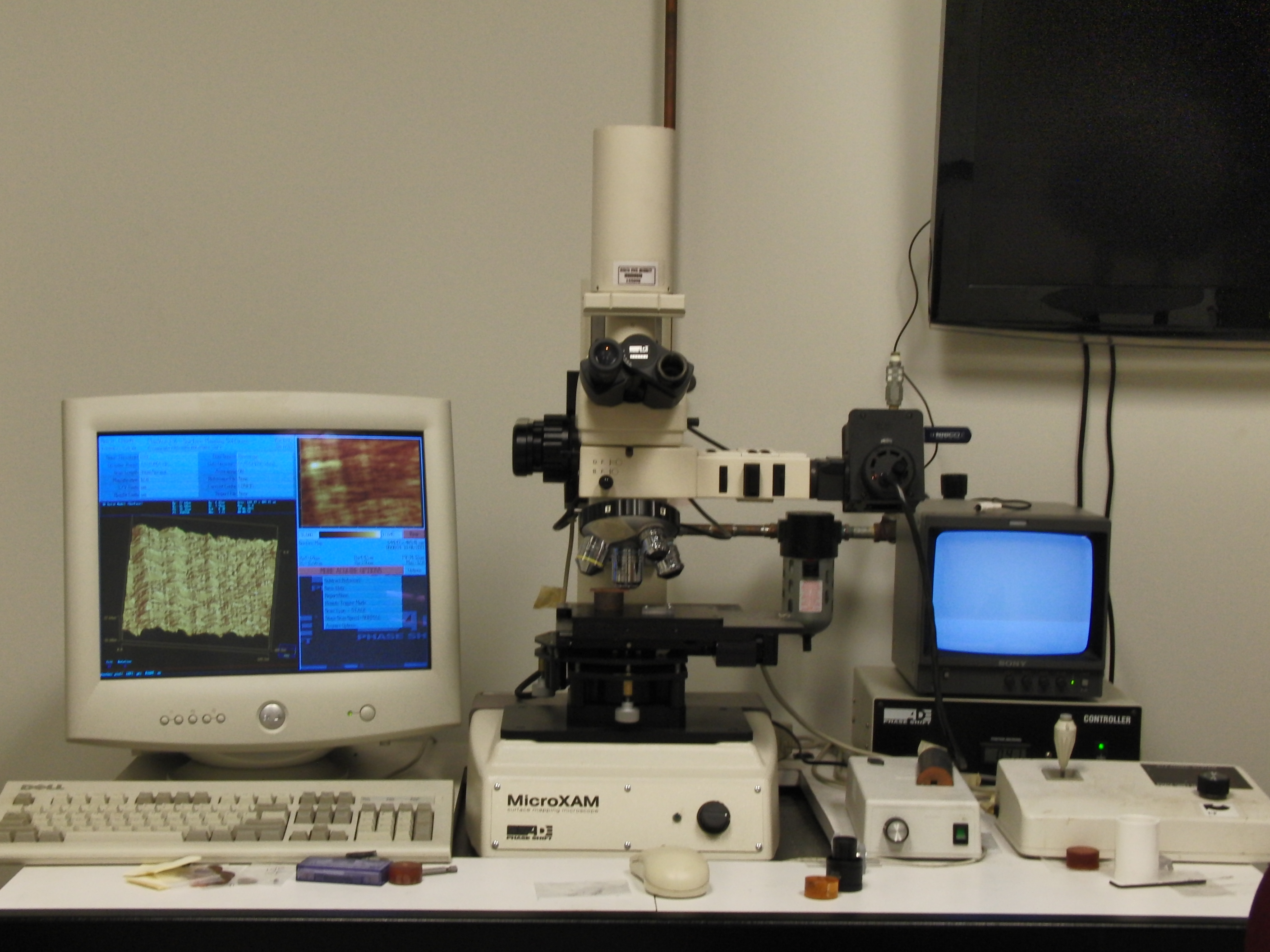

The Manufacturing Processes Research Lab consists of two machine tools: a high speed, high rigidity lathe (Setco spindle capable of 10,000 rpm, 30kW, 50m/s with 6" dia. workpieces), and a high speed linear slide (H2W, 5m/s max speed, 480lb max force, 30" stroke). These are complemented by a variety of analytical instruments for study of high speed machining processes. A custom built, patent pending, ultra high speed 3D StrainMaster high speed photography and digital image correlation system is built around a Leica MZ16 StereoZoom microscope with four SensiCam dual frame cameras and is capable of acquiring microscopic images at resolutions up to 860 lp/mm at frame rates greater than 100MHz. This system includes Digital Image Correlation software and can be used for performing 2D and 3D stereoscopic image correlation to identify the velocity distributions and deformation fields on surfaces under observation. This system is being upgraded, by the addition of intensified CCD cameras and high power lasers, under a current MRI grant, to one capable of simultaneous deformation and temperature measurements. Other instruments include a Pacific Advanced Technology Photon 6000 high speed infrared FPA camera, Hitachi digital CCD camera and recording system with Navitar Ultra Zoom 6000 microscope, Kistler 9272 4-axis dynamometer and data acquisition hardware, and a Micro-XAM 3D non-contact surface profilometer. We also have access to various CNC and manual lathes and milling machines and a Kodak Ektapro HRC 1000 high speed camera.

Ultra high speed 3D Strain Master system

|

|

Photon 6000 infrared camera

|

|

Zoller “Genius 3”

|

|

High speed, high rigidity custom built CNC lathe

|

|

High speed linear slide for linear cuts

|

|

MicroXAM 3D surface profiler

|

|

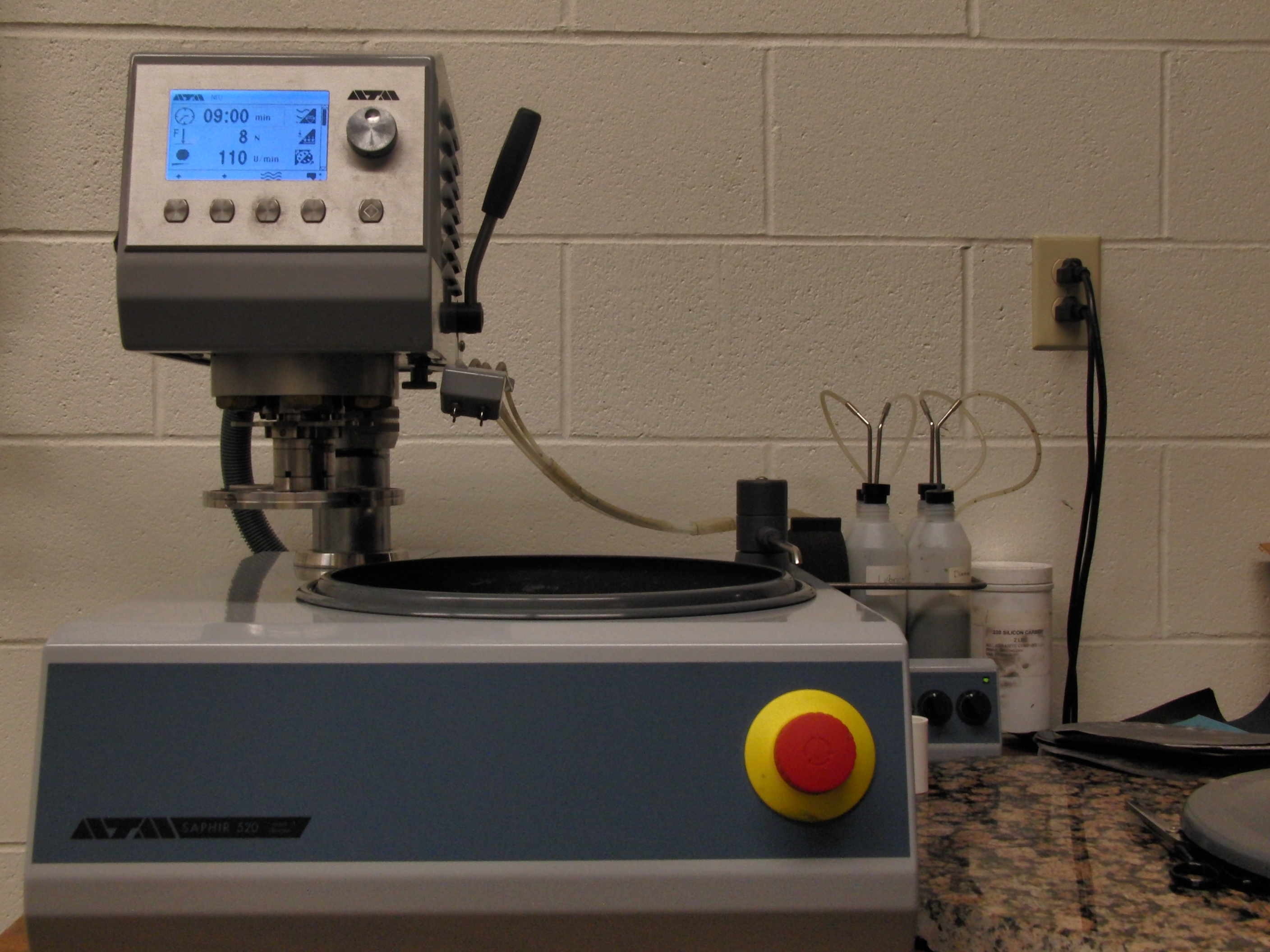

Saphir 520

|

|

Santro Tech Furnace |

|

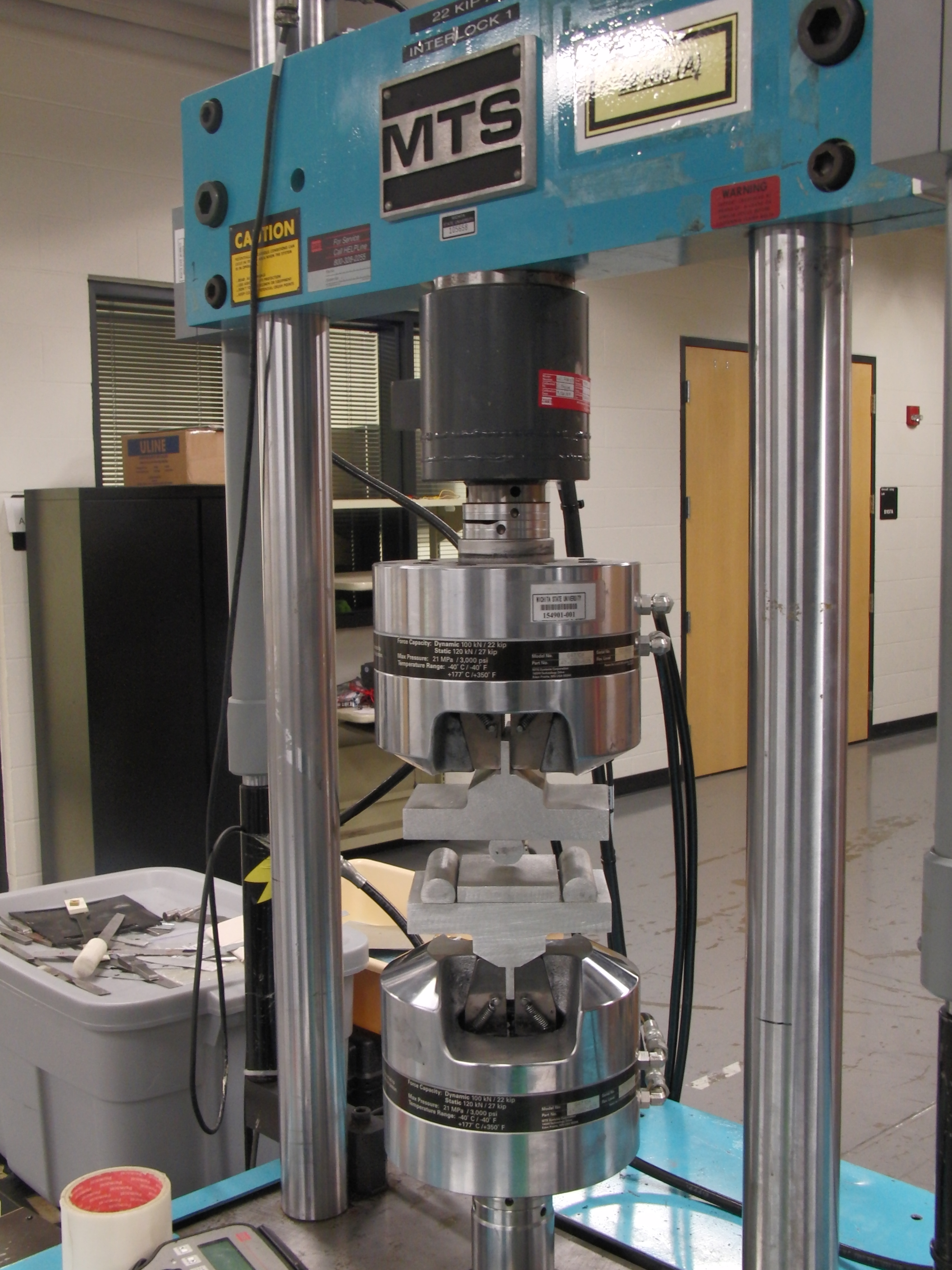

MTS Universal Testing Machine

|

|

|

Computers with access to HIPECC for computationally intensive tasks |