Current Projects

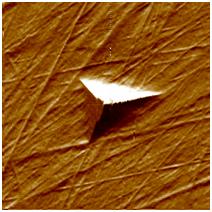

Measurement of Ductile Damage by Nanoindentation

In this project we study the feasibility of measurement of ductile damage using the results of nanoindentation test. The theoretical investigations include the study of ductile damage and the factors that affect the nanoindentation results. Besides, analytical and experimental efforts are required to verify and validate the designed test matrices. Experiments are performed on samples that are made using tensile test, compression test, cold rolling and machining. After preparing the specimens, they are polished and nanoindentaion tests are performed on the regions of interest. The final nanoindentation results along with metallographic studies will be used to address how feasible the use of nanoindentaion test is for measurement of ductile damage parameter.

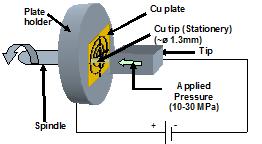

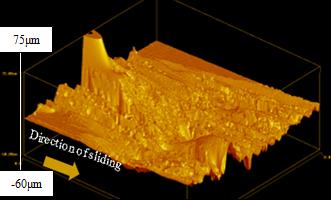

Experimental study of the effect of a contact conditioner on sliding electrical contacts

Sliding electrical contacts with high current density find their applications in Electro-magnetic rail guns, Electric motors and other switching devices. In this project we test high current density contact (500 & 1000 Amp/mm2) for the effect of thin layer of a contact conditioner such as a solid conductive lubricant using a custom developed pin on disc experimental setup. Controlled current pulses are passed through pin sliding over the disc keeping continuous contact. Coefficient of friction, contact resistance and number of sliding passes pin can make over the disc under specific contact pressure (10 & 30 MPa) are the key quantities measured. Surface Profilometry is performed over the pin contact path on disc for noting surface features, metal removal/deposition. Micro analysis of key experimental quantities is being done with an objective of defining the contact failure criterion.

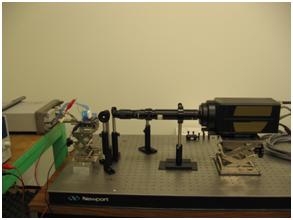

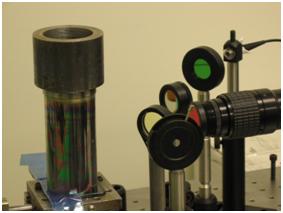

Temperature measurement by Laser Induced Fluorescent

In this project we have been trying to measure temperature by getting the fluorescent

intensity of DY: YAG. For this purpose we have used 355 wavelength laser to induce

fluorescent and a ICCD camera to capture it. Our main goals were:

• Setting up the ICCD camera for detecting fluorescence

• Investigate dependence of fluorescence on temperature

• Ratio of intensities in two wavelength ranges

• Compare with results reported in the literature

And our approaches were:

• Make a suitable target for basic measurements

• Develop optical setup to illuminate target with 355nm laser pulses and observe

resulting fluorescence at different target temperatures

• Obtain and relate average fluorescence intensity to temperature

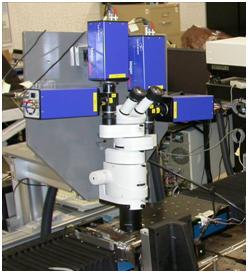

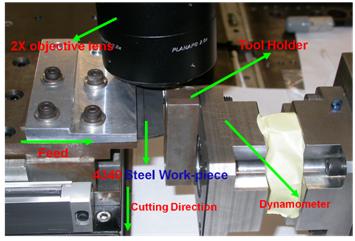

Experimental Determination of Velocity and Strain Rate Fields in Metal Cutting of AISI 4340 Steel

The aim of this project is to obtain velocity and strain rate fields in orthogonal cutting of AISI 4340 steel using high speed cameras and digital image correlation. The results obtained from cutting like strain rate, cutting force, thrust force, chip thickness etc is used to validate constitutive models in FEA. The cutting tests are easy to carry out and provide ample time for close microscopic examination of the deformation fields. Ultra high speed multi-cameras are used to acquire images in two quick successions using pulsed illumination from lasers. The cutting experiment is carried out on a linear slide with a capability of cutting from 0.1 mm/s to 4.5m/s with cutting force up to 2100N.

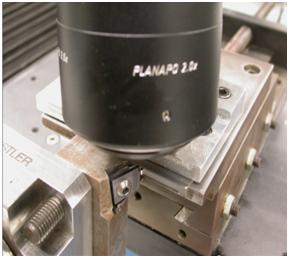

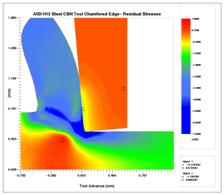

Tool Wear Modeling

In this project we develop experimental and numerical methods for determining the

velocity, stress and temperature fields in calibration cuts.

The test system is one grade of carbide tools (uncoated and coated) and hot rolled

AISI 4340 steel. The validity of this procedure will be determined by checking the

accuracy of the model over a wide range of cutting conditions.

The cutting forces and velocity fields around the tool cutting edge will be experimentally

determined. The input parameters are taken into FEA to match the velocity field to

the experimental velocity field, cutting forces and the chip thickness.

The main objective of this project is to develop experimental and numerical methods

for determining the velocity, stress and temperature fields in calibration cuts.

The developments will be made using one combination of tool and work materials, specifically

one grade of carbide tools (uncoated and coated) and hot rolled AISI 4340 steel, as

the test system. The validity of this procedure will be determined by checking the

accuracy of the model over a broad range of cutting conditions.

The key improvement needed to develop physically based tool wear models is to quantify

the physical variables accurately, under the cutting conditions used in the calibration

experiments. Another key requirement is to track the effect of tool wear on these

physical variables and use this additional data in determining the coefficients of

the tool wear model.

The cutting forces and velocity fields around the tool cutting edge will be experimentally

determined. The input parameters are taken into FEA to match the velocity field to

the experimental velocity field, cutting forces and the chip thickness.

Development and Application of IVE for Assembly Tasks

This project is continuing of the project titled as “Development and Application of Immersive Virtual Environment (IVE) for Assembly Tasks” that has been done by Weiwei Zhao and Dr. Vis Madhavan.

It includes some developments mentioned below

• Immersive Virtual Environment (IVE) development

• Mapping of key postures from Jack to IGRIP to playback the simulation in different

software

• Evaluation of accuracy of postures captured

• Accurately scaling the humanoid to match the immersed operator

• Mapping the postures from immersed operator to different sizes and proportions

humanoids